The means of feed and drink supply are specific to each species. They should be adapted to the height of the animals so that they can satisfy the vital needs of food and drink.

The dimensions of the trough must be chosen to conform with the required height, reach, and width of the feeding space for the animals to be fed, while providing enough volume for the amount of feed distributed at each feeding time.

The equipment should meet the requirements of the economic situation of the farm. This article discusses feeding equipment in accordance with animal breed.

Read Also: How often you need to Change Water in your Fish Farm

Feeding and Watering Equipment for Cattle in Agriculture

A. Feeding Equipment for Cattle

1 Mangers: Mangers are built-in receptacles for holding feeds from which the animals eat. Their efficiency is measured by the ease in serving, the small amount of space occupied, and the reduction of feed waste to a minimum.

Furthermore, the manger should be accessible and inviting to the animal or herd. For convenience, mangers may be classed as wall mangers and center-feed alley mangers.

Wall mangers are placed along the wall and reached from one side only, while center-alley mangers are accessible from both sides. They can be constructed with either wood or concrete.

2. Bunks: Two types of feed bunks (open grain and combination bunks) are used for grain, concentrates, and silage and the other for grain and roughage.

These bunks are built in convenient lengths of about 12 inches each. The width is about 4 inches for stability.

3. Open Grain Bunks: The bunks are constructed with 4×4 posts used with two-inch flooring and sides. Two-inch matched floor resting on 2×6 inch joists forms the bottom of the bunk.

Two by eight-inch sides, which give sufficient depth so that the grain is not pushed out. Cross and end bracing of 2×4 inch, which is necessary to strengthen the bunks since they receive rough usage.

4. Combination Bunks: The combination bunks are similar to the open bunk, except that a low rack is built over the feed box. Hay, fodder, or straw may be placed in this rack in addition to using the feed troughs for grain.

Long posts are necessary to support the framing for the rack. Two by fours are used for the rack, spaced ten inches apart.

This permits a six-inch opening, which allows animals to feed on roughage without pulling out large bunches and dropping them. The troughs catch the leaves which fall from the roughage and serve for feeding grain.

5. Feed Racks: Feed racks are built for holding forage, such as hay, straw, and other roughage. They may be built of a small size which is filled daily, or of a large size which will hold several days’ supply. Also, the rack may be mounted on a low-down wagon or truck. A good example of feed racks is hay racks.

6. Hay Racks: Hay racks consist of two main compartments: one in which the hay is placed and one in which the animals pull the hay before eating. The two compartments are separated by vertical bars spaced by 140 to 160 cm.

A manger at the base of the eating compartment collects the hay dropped by the animals, and this is eaten subsequently. The cattle gain access to the feeding compartment through a feed barrier.

7. Self-Feeder: Self-feeder has not been generally used in cattle feeding, but research records have shown that some cattle farmers have used it successfully for some years back. It consists of a large hopper-shaped bin with troughs at the sides.

The grain flows from bin to troughs by gravity as it is consumed by the animals. There are two different self-feeders. One is built on runners and may be moved about the feedlot, while the other is not movable; it is set on short posts, and shed shelters are provided on each side.

This latter feeder is filled from the ends, while the movable feeder may be filled from the ends or by lifting a section of the roof. Self-feeders for cattle should be wide and well-braced so they will withstand winds and rough usage.

They should be low down and compact to prevent upsetting. The length can be 12 feet and will hold about 200 bushels of small grain.

8. Automatic Concentrate Feeders: A concentrate feeder should not deliver too-small portions, otherwise feeding motivation is reduced. The availability of feed should also be very predictable to avoid unrewarded visits.

If the animals know when they can get concentrates and when not, they will quickly learn the relationship between visiting the feeder and obtaining concentrates.

In such systems, the concentrate feeder should be located in the feeding area, near the feed barrier, in rows of cubicles, or in an (exterior) exercise yard rather than in the lying area.

The advantages of the automatic feeder are the possibility to control the quantity of concentrates taken by animals each day and a decrease in labor.

B. Watering Equipment for Cattle

Water is very important for animals, and lack of water significantly affects production. Consequently, good-quality water supplied through adequate and accessible drinking facilities must be provided.

1. Water Trough: The size of a water trough depends on whether the herd is taken for watering periodically or is given water on a continuous basis. If water is limited, the length of the trough should be such that all the cows can drink at the same time.

A trough space of between 60 cm and 70 cm should be allowed for each cow. For free choice, the trough should be sized for two to three cows at a time.

One trough should be provided for every 50 animals. A well-designed trough is made of concrete. The length may be increased if necessary.

2. Water Bowl: The bowl drinkers used must have a minimum surface area of 0.06 m² and a water inlet flow rate of 0.16 L/s. The height of the bowl above the floor is 0.55 times the height of the animal withers.

The number of water bowls provided should be equivalent to 15% of the number of animals. The number of water troughs should be equivalent to one per 25 cows.

Troughs should be located in passages at least 3 m and preferably 3.5 m wide. Several animals may be drinking at the same time, and sufficient space is necessary for other animals to walk behind.

3. Automatic Drinkers for Cattle: Automatic drinkers activated by the animals provide a hygienic means of supplying water for cows and young stock.

When used in loose housing systems for cows, the bowl should be placed at a height of 100 cm and be protected by a raised area beneath it (1-meter-wide and 150–200 mm in height).

One bowl should be provided for every 10–15 cows. However, a nipple drinker without a bowl provides the most hygienic means of watering for young stock, but most nipples have a limited flow rate and can therefore not be used for calves older than six months.

Read Also: Worm Infestation on Ruminant Animals: Symptoms and Treatment

Feeding and Watering Equipment for Sheep and Goats

Generally, the type of equipment used for sheep and goats is similar to cattle as explained above. Most of the materials are made of wood, concrete, metal, or plastic and are movable.

1. Feeding Alleys and Troughs: For sheep and goats, when a shed is built for a large herd, a concrete feeding alley makes mechanized distribution of feed easier.

The trough may be separated from or included in the alley. With a crate trough, the animals eat from the trough from both sides and it is usually placed in the middle of the shed. This system is used in older buildings or on permanent pastures for hay.

2. Mechanical Trough: This has several advantages such as saving distribution time, and it is cleaned automatically, and the food is pushed back when dropped.

However, it is still expensive. The system used in sheep sheds consists of a belt conveyor drawn by a cable sliding along a metallic framework.

The cable winds up around a pulley, which is driven by electricity. At one end, a food bin receives the fodder. Concentrates can be distributed at the same place but separately.

3. Racks: Racks are used for feeding hay to the animals. Their size must be adapted to the type of bales that are used. A rack can be placed over the trough.

It is used only for bulk hay or small bales. In that case, metal is used as building material. Using round bales implies large-size racks.

They are round or square in shape, and a fixed yoke is set at the base. The basic principle is the same as for cattle racks.

Watering Equipment for Sheep and Goats

The general requirements for drinking facilities are similar for goats and sheep. Drinking-water requirements according to its physiological state, a ewe can drink 3 to 5 L of water per kilogram of ingested dry matter. But it is very important to allow animals to drink easily.

Thus, three conditions must be respected: the shape of the drinking facility, its location, and its height. For these animals, a water bowl is generally used. Manual watering equipment includes buckets, troughs, tanks, and tubs.

In some farms, automatic waterers have been used. Whatever type is used, cleanliness of the water is very important because sheep are reluctant to drink soiled water, which may affect their body system. The drinkers should be cleaned very often.

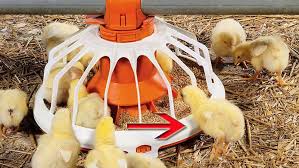

Feeding Equipment for Poultry in Agriculture

For laying hens in ground-level breeding, every 1000 hens should have trays in the starting period and 40 m of chain, that is, 8 cm of auger length per fowl, or 40 trays. Three systems are used: a spiral, a flat chain, or a trolley.

1. Spiral Feeding System: In a spiral system, the auger and the conveying device are one. The spiral lies at the bottom of the auger. It is operated by a clock.

2. Flat Chain Feeding System: The flat chain moves along the bottom of the auger. The forwarding speed is 12 m/min.

3. Trolley Feeding System: There are two types of feeding trolleys: a trolley with only one feeding box placed above the cages, in which a conveyor pushes the feed towards the downward pipes; and a side trolley with a feed box for each level on each side.

Poultry Watering Equipment

Drinking water requirements for poultry should be provided with sufficient cool drinking water without wastage. The drinking trough should be easily reached. The quality of the water should meet the local standards for drinking water.

In cage-breeding systems, the dripping system is used, or the suckling drinker into which the water is led by gravity from constant-level tanks located at the end of each battery.

In the cage, two drippers should be available to each hen. A device for water recovery (cup or gutter) is fitted below each drinker. This contributes to obtaining dry droppings.

However, for broilers, dripping systems (pipette) fixed on a feeding pipe and hanging inside the building, supplied through gravity, or round drinkers can be used.

Height above floor level depends on the size of the fowls and on the period (either starting or breeding).

Other Feeding Equipment in Livestock Production

1. Feeding Trailers: The equipment has a container for the feed whose bottom is mobile, and a screw or a side conveyor that drops the fodder into the trough.

2. Mounted Silo Unloaders: This machine can take the fodder from the silo and distribute it into the troughs. At the bottom of the machine, a chain conveyor and slats throw the fodder sideways.

Trailers and silo unloaders can include a system for distribution on both sides. The hay is either cut or torn from the silo. These machines generally can work at heights between 2 and 3 m.

3. Hydraulic Fork: The hydraulic fork is the simplest means for taking and distributing silage. However, it is impossible to spread the feed in the trough. It has to be piled first and spread later.

4. Mixer Trailers (Complete Diet): This machine has a system of mixing the feed so that a complete diet can be prepared. A weighing system with a gauge constraint allows for measurement of the quantities of feed put into the trailer.

The mixing of feed and concentrates is achieved by one or several screws that move the fodder.

5. Fixed Feeding Systems: In large breeding units, feed distribution can be mechanized with a conveyor. This is a fixed piece of equipment that conveys and distributes the feed into a trough.

Distribution is best with short minced feed. Generally, these pieces of equipment are limited in length, especially those with screws.

Do you have any questions, suggestions, or contributions? If so, please feel free to use the comment box below to share your thoughts. We also encourage you to kindly share this information with others who might benefit from it. Since we can’t reach everyone at once, we truly appreciate your help in spreading the word. Thank you so much for your support and for sharing!