Processing Pumpkins for Exportation begins with harvesting fully ripe pumpkins. Look for a hard rind and a deep orange color, and cut them from the vine with a few inches of stem still attached. Clean the pumpkins thoroughly using a soft brush and water, and let them dry completely.

Next, sort the pumpkins by size, color, and quality, discarding any damaged ones. Cure them in a warm, dry place for 10-14 days to toughen their skin and extend their shelf life. Apply a food-grade fungicide to prevent mold and decay, following the manufacturer’s instructions.

Prepare sturdy, clean packaging materials and pack the pumpkins gently with adequate padding to prevent movement. Label each package with essential information and complete all required export documentation, including phytosanitary certificates. Store the packaged pumpkins in a cool, dry place until ready for shipment.

Packaging Pumpkins for Exportation requires strong, durable boxes or crates. Line the packaging with protective materials like bubble wrap or foam to cushion the pumpkins and prevent bruising. Arrange the pumpkins in a single layer if possible, and fill any gaps with padding materials to minimize movement.

Seal the boxes securely with strong tape and affix clear, durable labels with destination addresses and handling instructions. Ensure the packaging complies with the destination country’s regulations and keep detailed records of the process. Inspect the packages for any signs of damage or issues before storing them in a cool, dry environment until shipment.

Exporting Pumpkins for Profits involves several key strategies. Start with market research to identify countries with a demand for pumpkins and understand their import regulations. Ensure compliance with export regulations and set competitive prices by factoring in production costs, transportation, taxes, and tariffs.

Plan logistics carefully, choosing reliable carriers and minimizing transit time and costs. Maintain high-quality standards, develop a marketing strategy, and establish effective sales channels.

Provide excellent customer service and monitor performance to identify trends and areas for improvement. Be ready to adapt your strategies and explore new markets to expand your business.

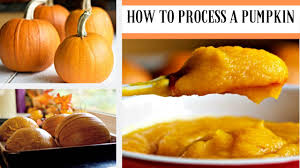

How to Process Pumpkins for Exportation

1. Harvesting: Ensure pumpkins are fully ripe before harvesting. They should have a hard rind and deep orange color. Cut them from the vine with a sharp knife, leaving a few inches of stem attached.

2. Cleaning: Remove any dirt or debris from the pumpkins. Use a soft brush and water to gently clean the surface. Make sure the pumpkins are completely dry before moving to the next step.

3. Sorting: Inspect each pumpkin for damage or imperfections. Sort them based on size, color, and quality. Only select pumpkins that are in good condition for export.

4. Curing: Cure pumpkins in a warm, dry place for about 10-14 days. This helps to toughen the skin and extend shelf life. Ensure good air circulation during this process.

5. Treatment: Apply a food-grade fungicide to prevent mold and decay. Follow the manufacturer’s instructions for the correct application.

6. Packaging Preparation: Prepare clean, sturdy packaging materials. Use containers or boxes that can support the weight of the pumpkins and protect them from damage during transit.

7. Packing: Place pumpkins gently in the packaging, avoiding overcrowding. Use padding materials, like straw or paper, to fill gaps and reduce movement. Seal the boxes securely.

8. Labeling: Clearly label each package with necessary information, including the origin, destination, and any handling instructions. Ensure labels are durable and water-resistant.

9. Documentation: Complete all required export documentation, including phytosanitary certificates and invoices. Ensure all paperwork is accurate and accompanies the shipment.

10. Storage: Store packaged pumpkins in a cool, dry place until they are ready to be shipped. Maintain proper ventilation to avoid moisture buildup.

Read Also: Nine (9) Nutrient Requirements of Rabbits

How to Package Pumpkins for Exportation

1. Choose Packaging Materials: Use strong, durable boxes or crates that can withstand the weight and rough handling. Ensure the materials are clean and free from contaminants.

2. Prepare the Packaging: Line the boxes with protective materials, such as bubble wrap or foam. This helps cushion the pumpkins and prevent bruising.

3. Arrange the Pumpkins: Place the pumpkins in the boxes, making sure they are not overcrowded. Arrange them in a single layer if possible, with each pumpkin separated to avoid direct contact.

4. Fill Gaps: Use additional padding material, like shredded paper or straw, to fill any gaps between pumpkins. This minimizes movement and reduces the risk of damage.

5. Seal the Boxes: Close the boxes securely with strong packing tape. Ensure all seams and edges are well-sealed to protect the contents during shipping.

6. Label the Packages: Affix clear, durable labels to each box. Include essential information such as destination address, handling instructions, and any required export documentation.

7. Check Compliance: Verify that the packaging meets the destination country’s regulations and standards for export. Adjust the packaging if necessary to ensure compliance.

8. Document the Process: Keep detailed records of the packaging process, including the number of boxes, contents, and any special handling instructions. This helps track and manage the shipment.

9. Inspect the Packages: Conduct a final inspection to ensure all boxes are securely sealed and properly labeled. Check for any signs of damage or issues before shipment.

10. Store Appropriately: Store packaged pumpkins in a cool, dry environment until they are ready for export. Ensure they are kept in conditions that prevent spoilage or damage.

How to Export Pumpkins for Profits

1. Market Research: Research potential markets and identify countries with demand for pumpkins. Understand local preferences and regulations for importing pumpkins.

2. Compliance: Familiarize yourself with export regulations, including phytosanitary requirements and customs documentation. Ensure your pumpkins meet all necessary standards for the target market.

3. Pricing Strategy: Set competitive prices based on market research and production costs. Consider factors like transportation, taxes, and tariffs when determining pricing.

4. Logistics Planning: Arrange for transportation and shipping. Choose reliable carriers and ensure they have experience handling agricultural products. Plan the logistics to minimize transit time and costs.

5. Quality Control: Maintain high-quality standards for your pumpkins. Regularly inspect and test the quality of your product to ensure it meets export standards.

6. Marketing: Develop a marketing strategy to promote your pumpkins. Use online platforms, trade shows, and industry contacts to reach potential buyers and create demand.

7. Sales Channels: Establish sales channels in your target markets. This could include distributors, wholesalers, or direct sales to retailers and consumers.

8. Customer Service: Provide excellent customer service to build strong relationships with buyers. Address any concerns or issues promptly and professionally.

9. Monitor Performance: Track your export performance and analyze sales data. Identify trends and areas for improvement to enhance profitability.

10. Adapt and Expand: Be prepared to adapt your strategies based on market feedback and changing conditions. Explore new markets and opportunities to expand your export business.

Read Also: Rabbit Feeds and Feeding Systems

Frequently Asked Questions (FAQs) About Pumpkins

1. What is the best time to harvest pumpkins?

The best time to harvest pumpkins is when they are fully ripe, with a hard rind and deep color. Typically, this is in late summer to early fall.

2. How can I tell if a pumpkin is ripe?

A ripe pumpkin has a firm skin that is hard to puncture, a deep color, and a stem that has turned brown and is dry.

3. How should I store pumpkins before exporting?

Store pumpkins in a cool, dry place with good ventilation to prevent spoilage. Keep them away from direct sunlight and moisture.

4. What are the key considerations for packaging pumpkins?

Consider using sturdy boxes, adding protective padding, and ensuring pumpkins are not overcrowded to prevent damage during transit.

5. Do pumpkins need to be treated before export?

Yes, applying a food-grade fungicide can help prevent mold and decay during transport. Follow the manufacturer’s instructions for proper application.

6. What documents are required for exporting pumpkins?

You will need export documentation such as phytosanitary certificates, invoices, and any additional paperwork required by the destination country.

7. How do I find buyers for my exported pumpkins?

Research potential markets, attend trade shows, and use online platforms to connect with buyers. Building relationships with distributors and wholesalers can also help.

8. What are common issues faced during pumpkin exportation?

Common issues include spoilage, damage during transport, and compliance with export regulations. Proper handling, packaging, and documentation can help mitigate these issues.

9. How can I ensure my pumpkins meet export quality standards?

Regularly inspect and test the quality of your pumpkins, and adhere to export regulations and standards for your target market.

10. What is the best way to set prices for exported pumpkins?

Set prices based on market research, production costs, and additional expenses like transportation and tariffs. Ensure your pricing is competitive while covering costs and generating profit.

Read Also: The Art of Waste to Jewelry Business