Normal storage including crop storage is defined as the keeping of foodstuffs open to the atmosphere subject to room temperature and humidity. In the real sense, crop storage begins immediately the crop is detached or harvested from the parent plant. The decomposition caused by fungi, bacteria and nematodes starts in the field and continues during the cause of storage.

Food self-insufficiency depends on increase production, reduced post- harvest losses, improved processing methods and improved product distribution. But how can increase in food production, improved processing methods, and improve product distribution be effective or possible if post- harvest losses are not to be studied and improved upon when the need arises.

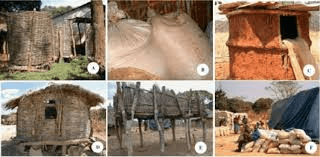

1. Traditional Methods of Food Storage

More than three-quarters of the agricultural output of African smallholder farmers is kept at village level for local use and stored using traditional methods. Storage at the household level offers several advantages:

It stores food close to the majority consumer.

It gives farmers easy access to their assets and facilitates sale transactions.

It does away with transport and handling costs and eliminates losses which occur at this level.

It serves as a source of information regarding the supply of grain on the market which informs production decisions.

If the household storage is still full when farming preparations are underway, this might signal that there is still an oversupply of the type of grain on the market.

An informed farmer may reduce his acreage from the over supplied grain to another crop. The type of foodstuff and the size of the crop to be stored determine the design and capacity of these facilities.

Farmers store their crops either outside, suspended or on platforms, or in granaries, or even inside their homes.

1. Areal Storage

Unshelled maize cobs and other un-threshed cereals are suspended in bunches or sheaves, using rope or plant material, under eaves, from the branches of trees or the top poles driven into the ground.

The grain dries in the air and the sun until it is needed by the farmer for consumption or marketing. The disadvantage is that the grain is exposed to the environment and pests.

2. Storage on the Ground

This is for temporary storage, following on immediately from harvesting and lasting only a few days, either because the farmer had not had time to bring in what he has harvested or because he wants to let it dry in this manner for a while when there is no prospect of rain.

Storage on the ground is not efficient and not good in tropical areas because of the high incidence of damp. If a farmer uses this method the grain should be placed on a tarpaulin.

3. Platforms

A platform consists essentially of a number of relatively straight poles laid horizontally on a series of upright posts. If the platform is constructed inside a building, it may be raised just 35 – 40 cm above ground level to facilitate cleaning and inspection.

Platforms in the open may be raised at least 1 meter above ground. Platforms are usually rectangular in shape, but circular or polygonal platforms are common in some countries. Grain is stored on platforms in heaps, in woven baskets or in bags. In humid countries fires may be lit under elevated platforms, to dry the produce and deter insects or other pests.

Instead of being horizontal and flat, the platform may be conical in shape; conical platforms are pointed at the bottom and are up to 3 meters in diameter. Such platforms facilitate drying because of their funnel shape.

At the top they consist of a frame of horizontal poles which is square, circular or polygonal in shape, against which the timbers which form the cone rest. These timbers meet at the bottom on a wide central supporting post.

4. Cribs

A distinct improvement on platforms, a crib has ventilated sides made of bamboo grass stalks or even wire netting. It should face such a way that the prevailing winds blow perpendicular to the length.

In humid countries where grain cannot be dried adequately prior to storage and needs to be kept well aerated during the storage period, traditional granaries (cribs) are usually constructed entirely out of plant materials.

This includes timber, reeds and bamboo which provide good ventilation. Storage cribs made of wood and chicken-wire have been introduced by NGOs. These worked well in Rwanda and rural parts of Uganda but were rejected by farmers in Kenya because the sides made of chicken wire made the contents visible and were easy to steal from.

One fault with the pictured crib is that the design does not include rat entry prevention measures.

5. Dwellings

Unthreshed cereals are commonly stored under the roof of dwellings, hanging from the roof timbers or spread out on a grid above the fire, the heat and smoke ensuring that the insects are deterred. These grain reserves are intended for day to day consumption because they are within easy reach and safe from theft and pests.

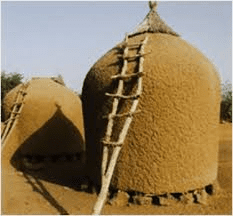

6. Mud Granaries

These granaries are made of clay which is sometimes mixed with fragmented plant materials (grass, twigs). In some cases the clay comes from termite mounds. They may also be constructed with clay bricks. They are insulated from the ground by means of wooden poles, clay pedestals or large stones.

They may be either circular or rectangular in shape; in the latter case the inside may be partitioned off into separate compartments. In Senegal mud granaries 3 m by 1.50 m are found with a central corridor leading to slates 80cm above the ground.

The paddy sheaves stored in them are dried by means of a fire which is kept burning in the corridor. In some regions, these granaries are covered with a straw roof or built completely of mud.

Some are more or less round with the tip pointing downwards and resting on stones. These mud granaries are common in Nigeria, Chad, Mali, Mauritania and Niger and are a cheap means of storage well suited to the dry climate of these countries.

While some are quite small, others have a capacity of up to 5 tons. Because they can be hermetically sealed, insects are unable to penetrate and find it difficult to develop once inside because of reduced oxygen.

The complete lack of ventilation means moisture content of the grain must not exceed 10% and the humidity must be less than 70%. These granaries are not resistant to persistent or heavy rainfall and care must be taken to seal up promptly the cracks which easily form with this type of material.

Read Also: Traditional Storage of Roots and Tubers

2. Traditional Maize Storage

1. Cribs

Traditionally, maize farmers use cribs of various types for storing their maize cobs in the sheath at the village level. These cribs have poor facilities for continuous drying of the maize, insect control and rodent control. An improved maize crib, has therefore been designed for use by farmers for effective storage of maize at the Village level.

2. Construction of the Maize Crib

The site for the Crib: Your crib should be constructed on a level sit which is clear of trees and bushes. This enhances good ventilation c the maize in the crib and makes the maize dry quickly. If possible, is better to build your crib on a raised area of ground where there good breeze.

The Shape of the Crib: Your crib should be rectangular in shape. The length can be of any measure depending on the quantity of maize you wish to store. The width should be narrow, from 90 cm in wetter areas to 150 cm in dry areas.

In wetter areas of the forest zone, the 90 cm width should be used whereas, in the drier areas of the Western States, Delta State and the Eastern States, the wider crib may prove satisfactory. In most areas, a standard width of 120 cm. is usually recommendation.

One ton of maize would require a 150cm long by 120 cm wide and 120 – 150 cm high crib storage space.

Orientation of the Crib: The long side of your crib should face the direction of the prevailing wind. This enables the wind to blow through the mass of maize cobs more easily and allows efficient drying.

Most rapid drying can be achieved in the 90 cm. wide crib and to enable free passage of air, the crib should never exceed 150 cm in width.

Construction of the Crib: The crib is constructed in two basic parts;

- The platform carrying the weight of the maize cobs and

- The frame-work which supports the sides and roof of the

Procedure

Select the location, size and orientation of your crib and mark out the basic dimensions on the ground.

Poles to support the platform for the maize should be let into the ground to a depth of 3Cf- 40 cm. at points corresponding to the corners of the crib and at reasonable intervals along the length and middle of each end of the crib.

The overall length of these poles should be 160 – 170 cm. so that, when let into the ground, they are able to support the platform at a height of not less than 120 cm. from the ground.

The number of these poles you require, will depend on the size and shape of your crib. Bamboo is recommended, where available.

Horizontal poles are fixed by nails or ropes to the top of platform supporting poles, first lengthwise along the outer edges of your platform and then across the width. You will now have a rigid platform to support your maize.

Two long poles of about 400 cm. length are let into the ground at the midpoint of each end of your crib. These will support your ridge pole. Depending on the length of the crib, additional centrally located ridge-supporting poles may be required.

A series of vertical poles – 300 cm. long should then be erected corresponding to, and close to the poles supporting your platform frame. These poles will support the side of the maize compartment and, together with the ridge pole, the roof of the crib.

To stabilize the structure, a horizontal pole is lashed or nailed at each end of the crib to the top of the corner poles and to the ridge supporting poles, the ridge pole is fixed in position and further poles to support the outer edge of the roof are fixed horizontally along the outer top edges of the crib. You should now have a rigid upper framework for your crib.

A light framework of palm-leaf midrib or split bamboo can now be fixed from the ridge poles to the upper horizontal poles at the side of the crib and by weaving in further material in a lattice base for your crib roof is constructed.

The roof is made of grass (preferably – ekong grass), or raffia leaves which is knitted or woven in the traditional way and then fixed to the roof framework of the crib.

A retaining wall for your maize must now be constructed. This consists of horizontal poles nailed or lashed to the roof supporting poles up to the level to which the maize cobs are to be stored. You should, of course, leave a gap at one end of the crib for loading and access.

From the inside of the crib – 2cm mesh chicken wire netting should be used to cover the walls and floor of the crib. This should be firmly fixed to the main framework of the crib. Alternatively, a palm midrib or split bamboo lattice may be used.

This must be firmly secured to the main frame of the crib and made strong enough to support the weight of the maize cobs especially across the crib floor.

If you have used bamboo for the vertical poles of your crib framework, you may not get a problem with rats attacking your maize, provided your platform is at least 120 cm. above ground level as rats are not easily able to climb the bamboo poles.

Where you have used other poles for your crib frame, you must make rodent guards for all the legs of your crib to prevent rats from getting to your maize. Rodent guards are made from iron or aluminum sheet which is cut to shape so that when wrapped around the leg of the crib, a complete cone is formed.

These rodent guards should be fixed at a height of from the ground with the open end of the cone facing down-wards. When in position, the outer edges of the cone should be about 12 cm. from the leg of the crib and no space should be left at the top end through which a rat may pass.

A further precaution is to keep the area around your crib clear. Rats can climb up plants growing close to, or farm implements etcetera, carelessly left leaning against your crib, and from there gain entry into your crib.

Variations in Materials: The description given above is for the basic structure of a crib which can be made entirely from local materials (except for the rat guards). It is possible to construct cribs of a more permanent kind using other materials, i.e. by using treated timbers for the framework and galvanized iron sheeting for the roof. Another type can be made entirely of iron.

Read Also: Problems Associated with Crop Products Storage

Methods of Storage and Insect Control

After harvesting, the husk is removed from the maize ear leaving the cobs which will be at about 25% moisture content at this time.

The cobs are carried to the site of your crib in baskets or in bags and loaded into the crib for storage.

As each bag is emptied and spread in the crib, one of the insect control measures, described below is applied to the maize from that bag. In this way, you will get an even distribution of your insecticide.

The Application of Insecticide Dusts

The application of Pirimiphos Methyl 2% dust for the protection of maize in cribs at a dosage rate of 10 ppm should be effective for 4 months. This dust is available from Chemical and Allied Products Nigeria (Ltd.) formerly ICI (Nigeria) Ltd.

The procedure of application is detailed below. The quantity to be used per bag of maize would quarter fill a cigarette tin. Where scales or balances are available, the quantity required is 45 gmsper bag of maize.

Obtain a cigarette tin or any other tin of the same size.

Perforate its closed end with a number of small holes.

Fill the tin up to ¾ full with (45 gm) of Pirimiphos Methyl dust and replace the lid.

Apply the contents of this tin evenly over the contents of one bag (produce bag) of maize after loading into the crib.

Repeat this procedure for each bag of maize loaded into the crib.

Treat all the maize loaded into the crib bag by bag until the crib is full.

The maize should now be protected against heavy insect attack for about four months.

If further storage after four months is desired, further dust may be applied to the top and sides of the maize in the crib.

Maize treated with insecticide should not be used for eating for about two months after application. After two months, it is considered that the treated maize is safe for consumption after normal processing.

Pirimiphos methyl is also available as 2% emulsifiable concentrate called Actellic which is mixed with about 3 times its volume of water and used to spray the maize cobs evenly as they are loaded into the crib. This also protects the maize for 4 – 5 months. At intervals of about 3 months, the surface and outer cobs can be re-sprayed with liquid Actellic.

Read Also: Introduction to Waste Management and Sources of Waste

Frequently Asked Questions

We will update this section soon.