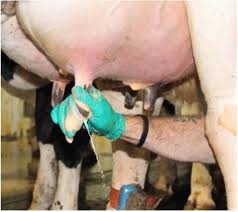

The milk secreted from a cow’s udder is usually sterile. However, it invariably becomes contaminated during and after milking by the milker, milking equipment, utensils, cooling, storage, and processing.

Milk is an excellent medium for bacteria, yeasts, and molds, which are common contaminants. Contamination from improperly cleaned utensils or cans accounts for about 60% of cases, making it the highest contributor to contamination.

Dairy farmers and producers are responsible for producing milk under clean and hygienic conditions, ensuring it is protected from contamination by dirt at all times. This involves employing appropriate techniques to clean and disinfect milking equipment, utensils, and storage cans.

The ability of raw milk to retain its quality during storage, as well as its safety for consumers, is directly related to its bacterial content.

Good-quality milk is essential for producing high-quality dairy products. In most countries, bacterial content is one of the factors considered when determining the payment for milk.

Read Also: Diseases Fishes can get from Feeds

Samples of Milking Utensils

- Milking Buckets.

- Milking Machines.

- Teat Cups.

- Milk Cans.

- Strainers and Filters.

- Udder Washing Equipment.

- Teat Dip Cups.

- Milk Cooling Tanks.

- Milk Testing Equipment.

- Cleaning Brushes.

- Milk Recording Equipment.

- Milk Transfer Equipment.

- Milk Weighing Scales.

- Milk Storage Jars.

- Milk Churns.

- Milk Pasteurizers.

- Milk Homogenizers.

- Milk Separators.

- Milk Thermometers.

- Milk Clotting Equipment.

- Milk Transport Tanks.

- Milk Bottling Equipment.

- Milk Testing Kits.

- Milk Sampling Equipment.

- Milk Agitators.

- Milk Dispensers.

- Milk Frothers.

- Milk Warmers.

- Milk Fat Testers.

- Milk Storage Bags.

- Milk Carton Fillers.

- Milk Can Lids.

- Milk Can Carriers.

- Milk Can Cleaners.

- Milk Can Labels.

- Milk Can Seals.

- Milk Can Lids with Strainers.

- Milk Can Lids with Spouts.

- Milk Can Lids with Handles.

- Milk Can Lids with Thermometers.

- Milk Can Lids with Pressure Valves.

- Milk Can Lids with Sampling Ports.

- Milk Can Lids with Agitators.

- Milk Can Lids with Heating Elements.

- Milk Can Lids with Cooling Elements.

- Milk Can Lids with UV Sterilizers.

- Milk Can Lids with Air Filters.

- Milk Can Lids with Moisture Sensors.

- Milk Can Lids with Pressure Gauges.

- Milk Can Lids with Temperature Gauges.

Read Also: Reasons why Fishes Refuse to Eat their Feed and How to Correct it

Procedure for Cleaning Milking Utensils

1. Pre-rinsing with Water: Pre-rinsing with cold or lukewarm water should always be carried out immediately after emptying the vessels. Otherwise, milk residues will dry and stick to the surfaces, making them harder to clean.

If there are dried milk residues on the surface, soaking the equipment may be beneficial to soften the dirt and make cleaning more efficient.

After rinsing, scrub the utensils or pails thoroughly with a suitable brush, using hot water and an effective dairy cleaner.

Approximately 15 grams of the cleaning mixture will be required for a utensil with a 10-liter capacity. After scrubbing, rinse the utensil with hot water. The water temperature should be above 50°C.

2. Washing and Sanitizing:

Wash the utensil again with sufficient cold water (or tepid water during cold seasons) to remove any traces of detergent. Sanitize the cleaned utensils with an acceptable sanitizing agent, such as iodophors or chlorine solutions (50-200 ppm of active compound), to disinfect them.

3. Drying and Storage:

Properly cleaned vessels should be placed in an inverted position to allow complete drainage of water, preventing contamination from air, insects, rodents, or reptiles. Dry, cleaned utensils should be stored in an area protected from dust, dirt, and other contaminants.

4. Hot Water Sterilization:

For hot water sterilization, the temperature should be as close to the boiling point as possible and never below 85°C. The utensils should be immersed for 20 minutes. If immersion is not possible, boiling water should be poured over the milk-contact surfaces until they are too hot to touch.

Do you have any questions, suggestions, or contributions? If so, please feel free to use the comment box below to share your thoughts. We also encourage you to kindly share this information with others who might benefit from it. Since we can’t reach everyone at once, we truly appreciate your help in spreading the word. Thank you so much for your support and for sharing!

Read Also: Treatment for Drinking Water Production