Approximately 75% of world fish production is used for human consumption and the remaining 25% is used to produce fish meal and oil. Fish meal is a commodity used as feed for livestock such as poultry, pigs and farmed fish and fish oil is used as an ingredient in paints and margarine.

Currently, only about 30% of fish produced for human consumption are marketed fresh. The supply of frozen fish fillets and fish, in the form of ready-to-eat meals and other convenience food products is growing in both developed and developing countries.

The end products from fish processing may be fresh, frozen or marinated fillets, canned fish, fish meal, fish oil or fish protein products, such as surimi.

Surimi is an important fish product, with the majority of catches for some species used solely for its production.

Fish processing most commonly takes place at on-shore processing facilities. However some processing can take place at sea, on board fishing vessels — for example the gutting of oily fish. In some regions of the world, where large sea fleets operate, processing can also take place on board fishing vessels.

For some sea fleets, 100% utilization of the catch may be required by legislation. This means that the entire processing operation, including fish meal and oil production for offal and fish waste, takes place on board the fishing vessels.

Advanced Fish Processing Methods

1. Filleting of White Fish

Filleting involves a number of unit operations: pretreatment, fish filleting, trimming of fillets, packing and storage. These processes generally take place within separate departments of the fish processing plant.

White fish species have low oil content and, unlike their oily fish counterparts, are generally gutted, cleaned and sometimes de-headed onboard the fishing vessel. The fish are kept on ice in boxes before being delivered to the fish processing plant.

On arrival at the plant, fish may bere-iced and placed in chilled storage until required for further processing.

Pretreatment

Pretreatment of the fish involves the removal of ice, washing, grading according to size and de- heading, if this has not been done previously. Large fish may also scaled be before further processing.

Filleting

The next step in the process is filleting, which is generally done by mechanical filleting machines. The filleting department is generally separated from the pretreatment area by a wall, to prevent workers and goods passing from the non-sterile pretreatment area to the sterile filleting area.

The filleting machines comprise pairs of mechanically operated knives which cut the fillets from the backbone and remove the collarbone. Some fish fillets may also be skinned at this stage.

Trimming

In the trimming department, pin bones are removed and operators inspect the fillets, removing defects and any parts that are of inferior quality. Off-cuts are collected and minced.

Depending on the final product, the fillets may be cut into portions according to weight or divided into parts such as loin, tail and belly flap. As a final step before packaging, the fillets are inspected to ensure they meet product standard.

Packaging and storage

Fresh products are packaged in boxes with ice, the ice being separated from the products by a layer of plastic. Frozen products can be packed in a number of ways.

Fillets or pieces can be individually frozen and wrapped in plastic, but the most common method is for them to be packed as 6–11 kg blocks in waxed cartons. The blocks are typically frozen and then kept in cold storage.

2. Fish Meal and Fish Oil Production

Fish meal and fish oil are produced from fish that are caught specifically for this market, by-catch from fishing activities and solid waste from filleting and canning.

Fish meal and fish oil products have a high nutritional value. Fish meal is used as feed for livestock and farmed fish, and the oil is used as an ingredient in paints and margarine.

Fish meal is derived from the dry components of the fish, and the oil from the oily component. Water, which makes up the rest of the fish matter, is evaporated during the process.

Most fish meal and fish oil production processes are automated and continuous, and comprise several process lines, each with a certain processing capacity. Production rates vary considerably, according to the season and types of fish being processed.

Read Also : Food Organisms and Feeding Habits of Fish

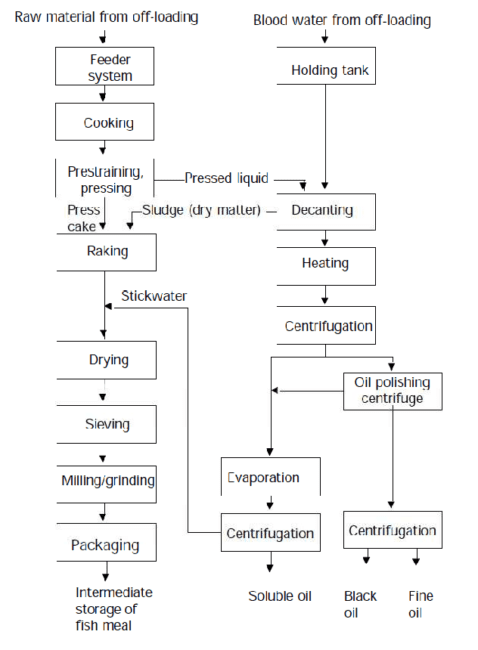

The steps involved in fish meal in fish oil production are summarized in figure1.

Off-loading

On board the fishing vessels, the catch is normally stored in tanks of water. Upon arriving at the processing plant the fish are pumped to holding bins, where they are stored until required for processing. Extra sea water may need to be added to pump the fish.

Fish Meal Process

From the storage bins, the fish are transported by screw conveyors to a cooking process which acts to coagulate the protein. The cooked mixture is then screened, using a strainer conveyor or a vibrating screen, and then pressed to remove most of the water from the mixture.

The pressed cake is shredded and dried, using an indirect steam drier or a direct flame dryer. The meal passes through a vibrating screen and onto a hammer mill, which grinds it to the appropriate size. The ground meal is automatically weighed and bagged.

Fish Oil Process

The pressed liquid generated from the previous processes passes through a decanter to remove most of the sludge, which is fed back to the meal dryer. Oil is separated from the liquid by centrifuges, polished and refined to remove any remaining water and impurities.

The separated aqueous phases, referred to as stick water, is concentrated in an evaporator and then added to the pressed fish meal prior to being sent to the dryer.

Overview of Fish Preservation Processing

An abundant fish catch is experience in the dry season. During this period, ponds, lakes and streams experience reduced water level, for easy harvest.

Thus, period of fish scarcity is often encountered especially during the flood and raining seasons, during which fish are in short supply. Thus, it is imperative to process and preserve some of the fish caught in the period of abundance, so as to ensure an all year round supply.

This will invariably reduce post-harvest losses, increase the shelf-life of fish, and guarantee a sustainable supply of fish during off season with concomitant increase in the profit of the fisher folks.

Fish processing is still predominantly undertaken manually in most developing and under-developed countries around the world. Traditional fish processors adopted open fire or simple smoking oven such as halved cut drum oven, rafters and mud oven to improved technology such as dryer, chorkor kiln and gas oven.

The different types of fish preservation techniques practiced are brining/smoking, drying, hot or cold smoking, smoke-drying, smoking with pepper, frying and sun-drying. Most common of all these processing technique was smoke-drying.

This could be adduced to the fact that most of the fish communities have no access to electricity to freeze their products. Electricity itself is fast becoming a less reliable source of energy for fish processing and preservation.

Despite the rudimentary nature of process of traditional methods, and lack of control over the drying rate, sometimes results to under-drying or over-drying, and expose the fish to unexpected winds, dust, dirt, insect infestation, and contaminants such as flies.

These methods still remain predominant in most countries. Most of the processing technique favours the use of drum oven and mud oven. For the improved technology, electric dryer, chorkor kiln and gas were not common in the processing centers.

Losses during fish processing were significant in traditional processing method compared to improved technology. To reduce post-harvest losses and to improve the quality of fish and fishery products, traditional processing technology must be improved upon.

This includes upgrading the traditional fish processing technology and adoption of solar dryer. The acceptability of mechanization of fish processing operations are hinged on the following factors based on the fish processors comments; literacy level, cost of the machines, level of awareness, infrastructural facilities available such as electricity, tap water or borehole water and accessible roads.

High incidence of fish losses is a major impediment to the realization of government goal towards increasing the contribution of the fisheries sector to the overall national economy.

The use of appropriate technology which is a radical approach to stem up production and processing technique, has become subordinate to social need, and is of paramount importance.

The need to mechanize fish processing techniques has drawn the attention of national agricultural research to devote utmost interest and resources to engineering research in operation, to minimize the drudgery, reduce labour operation, and unsanitary and inherent unhygienic handling that are mostly involved in the traditional manual operations.

Artificial dryers such as solar dryer, kiln, and oven and so on have long been in existence, some of them are powered electrically, by sun, gas or natural fuel such as firewood, charcoal, wood and saw dust.

The drying of fish in oven consists of a period of several hours in which the fish is cooked followed by a period drying with low burning fire, producing only a moderate amount of smoke. The length of this latter period varies with the required keeping quality.

The moisture of the dried products varies between an estimated 40percent in the higher ranges and 10-20percent in lower. The quality of the product is judged on degree of drying, appearance, damaged and insect infestation is influencing the price.

Smoked fish as source of foreign exchange is gradually losing ground. This is adduced to the fact that exportation of processed fish to developed countries is becoming increasingly stringent because of the emerging set of Food Safely and Agricultural Health Standard, along with buyers changing their requirements.

In summary, Traditional fish products (TFPs) are usually produced by applying old preserving methods such as salting, fermenting, drying and smoking. These products also greatly varies amongst the countries as well as within the same country by using many different applications such as differences in additives, percentage of salt or vinegar and maturing temperatures.

Moreover, modifications in these techniques are also known due to food safety issues and changes in customer preference of new generation. Although such processing/preserving methods have been known as old techniques for many years, they have still wide acceptance around the world because of their specific taste and aroma.

Due to their specific characteristics for varying many types, they have both advantages and disadvantages.

Traditional fish processing and preservation were originally developed to preserve fisheries products for a long storage life by either lowering water activity (aw) and/or changing pH of the products.

In addition, preservation was also carried out by applying antibacterial activity of salt and/or smoke components or other preservative compounds to increase shelf-life and improve safety of such products.

Although new technologies such as canning, high pressure processing (HPP) and modified or controlled atmospheric packaging (MAP, CAP) methods have been developed to improve safety of seafood products, traditional preserving methods of fish products have still wide acceptance around the world due to their accustomed taste and aroma.

Despite the preserving aim of such traditional methods, these products are still under risk of several hazards due to following reasons:

(i) These products have long maturation time,

(ii) They are generally consumed without further cooking,

(iii) Changes in the original methodologies over the years such as decreasing salt content.

The end products from advanced fish processing may be fresh, frozen or marinated fillets, canned fish, fish meal, fish oil or fish protein products, such as surimi.

Surimi is an important fish product, with the majority of catches for some species used solely for its production.

Fish processing is still predominantly undertaken manually in most developing and under-developed countries around the world.

Traditional fish processors adopted open fire or simple smoking oven such as halved cut drum oven, rafters and mud oven to improved technology such as dryer, chorkor kiln and gas oven.

Read Also : Ways To Generate Income From Household Hazardous Waste