Grain storage with modern storage structures help protect against crop losses from insects, rodents, moulds, theft, and fire, traditional designs are not always effective, and building them is difficult for poor communities where the hardwood supply is limited due to deforestation.

Designing of Modern Storage Structures

Modern structures should be designed such that they meet certain basic requirements with regards to location, accessibility and use. The following is a basic guide on the requirements of modern storage structures and systems.

Basic Requirements and Recommendations for Storage Structures

1. Store Site

Should be easily accessible throughout the year, should be sited above flood plains and should not be liable to flooding and the area must have good water drainage.

Sufficient space to maneuver delivery or collection vehicles.

2. Floors

Floors should be above ground level with sufficient elevation to allow drainage.

They should be crack-free reinforced concrete.

There should be vapour proof barrier under the floor and up to the walls to prevent dampness rising in the walls from the ground.

3. Walls

The inside surface must be plastered with cement/sand and mortar (essential for cleaning and pest control).

The outside surface must be plastered with cement, lime and sand (helps in keeping the store cool and easy to clean).

The walls should have windows or openings for ventilation designed not to allow birds or rats to enter.

They should have at least two doors wide enough to allow loading in and out.

Read Also : Packaging Materials and Modified Atmosphere Packaging Films

Painting the bins and or walls white (both inside and outside) can reduce the heat absorption by the walls and this can lower temperatures by up to 5 degrees and makes observing insect infestation easier.

The roof must not have any holes of leaks.

4. Roof

Must be designed to shed water quickly without leaking.

Must keep out pest like rodents, birds, insects, dust and heat.

Roof overhang at eaves level should be sufficient to shed rainwater clear of walls and help to keep the walls cool.

Gutters and draining pipes are not always necessary they get blocked and allow rodent entry in not properly managed.

5. Doors

All doors must be secure and rodent proof.

Doors must be large enough to allow for loading in and out and positioned for better inventory management and supplementary ventilation.

5. Ventilation

Proper ventilation is necessary for the reduction of humidity which encourages pest development.

Large doors can provide sufficient, controllable ventilation in the absence of eaves-level ventilation in stores that are regularly opened daily when full.

6. Pest Proof

Windows should also be screened if they are less than 1 m from the ground since rodents can jump this height.

– Granaries and drying platforms should be erected on large stones or platforms (which must be at least 80 cm high)

They should be reinforced with conical rat guards made of 0.50 mm thick steel plate, 25cm in diameter

– Buildings must be protected by ensuring that all the means of access close properly and are made of materials that are resistant to attack.

Rodents must be prevented from climbing along the posts, pipes, cables and rails in contact with the building and guards must be fitted to all these possible means of access

7. Hygiene

As with any grain warehouse, the interior should be designed and built to facilitate cleaning platforms, farm stores, and communal warehouses.

On farm storage is designed to handle and store production from the farm and will consists of small to medium structures like drums, cocoons.

On farm Modern Storage Structures

1. Metal Silos

Metal silos (including recycled oil drums) have emerged as efficient and low cost storage containers for the storage of cereal grains and pulses.

Inaccessible by rodents, efficient against insects, sealed against entry of water, drums make excellent grain containers.

However they should be protected from direct sunshine and other sources of heat. To avoid condensation they should be located in shaded and well ventilated places

2. Hermetic Cocoons

A relatively new development is the hermetically sealed bag or cocoon of various sizes (1 – 300 metric ton), which appear to offer good possibilities to store grain in a variety of quantities.

These cocoons are being used in Kenya with some success. The hermetic bags work on the principal that grains releases carbon dioxide which rapidly replaces the oxygen in the sealed container. Once oxygen is exhausted, the pests die and fungi cannot spread.

For these sealed units to work effectively, they need to be completely filled quickly and only open when the entire contents have to be used.

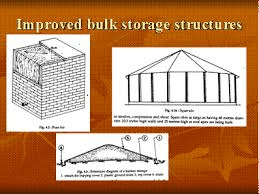

3. Farm Stores

Smaller stores are built with timber on a raised platform. The supporting poles should have rodent proof fixtures to prevent rodents from climbing or jumping into the store.

Larger stores may be constructed using iron sheeting or concrete and should meet the following standards:

The floor of the inside of the store should be above the level of the ground outside (to prevent dampness and rain entering).

Ideally there should be damp proofing under the floor and in the walls.

Ventilation points should be placed in the walls – these should be covered with screens to prevent rats, birds and insects entering.

The store should have a large well-fitting door to allow carrying bags in and out of the store and for allowing good aeration.

The stores should preferably be built a distance from the residential house so as to avoid fumigants and other storage chemicals filtering into the residential dwellings.

4. Communal Warehouses

Where farmers come together in formal groups they often consider establishing communal stores that are managed by a trained store manager.

The individual farmers can consolidate their stocks ready for the market by delivering to the communal store.

This arrangement may be the better option for small holder farmers who do not have the capital to put up own stores, have limitations of land available for the store or do not know how to store commodity well for extended periods of time.

These stores work extremely well as bulking centers where large traders come and pickup truck loads of commodity (preferably of the same quality) at one time.

The advantage to the big buyer is the reduction in the cost of buying through multiple aggregate traders with their multiplied handling costs.

5. Flatbed Warehouses

The majority of warehousing in Eastern Africa entails flatbed warehouses in which the commodities are stored in bags on pallets in large stacks. These warehouses range from 2,000 to over 15,000 tons.

Essentially they are larger versions of the communal warehouse. Generally they will have more than one set of doors for access.

Any ventilation openings under the eaves should be covered with screens that keep out rodents, birds and insects. Often there will be a separate grading room as well as an office for record keeping.

6. Open Sacs

This form of storage has been used successfully in Zimbabwe in the late 80‘s and early 90‘s. With proper planning, careful preparation and the right management this form of storage can fill in the gap where there is a huge shortage of storage space.

In this form of storage quantities of upwards of 5000 tons can be stored for periods of up to 2 years or more.

The other advantages are that the initial investment is very low and local materials can be used in preparing the stacks and the stack can be constructed anywhere, as long as the place is secure and the ground is suitable..

The disadvantages are that it requires good security especially when there is a shortage of grain in the community. It requires trained and experience personnel to construct the stacks and the preservation of quality through pest control.

Special bags which are strong and UV protected have to be used and if the grain is to be stored for long periods. The stacks can be constructed with channels to improve ventilation.

7. Grain Silos

Silos are an efficient method of storing grain; bulk grain takes less space and can be handled mechanically reducing bagging and handling costs.

Recycling grain in silos helps through aeration to reduce potential increases in grain temperature.

Read Also : Handling, Labeling, Storage and Delivery of Finished Feed Products

This is essential in silo management. There are different types of silos of various sizes for storing grain in bulk.

Silos are either constructed from concrete, bricks or sheet metal bolted together. Bolted corrugated steel silo models are becoming popular in most grain producing countries because they are effective and relatively cheap.

The disadvantage of bulk facilities is that in the case of underutilization they cannot be used for other activities.

In conclusion, the storage structures used depend on the construction material available, amount of produce to be stored, the type of produce, prevailing climatic condition of the area, purpose of storage and the resources of the farmer, in particular the availability of labour and capital.

The storage structures used depend on the construction material available, amount of crop produce, prevailing climatic condition of the area, socio-cultural aspects of storage and the resources of the farmer, in particular the availability of labour and capital.

In the humid forest zone yam is stored in a yam barn which is the principal traditional yam storage structure in the major producing areas.

Stores offer shelter to the grain, and in addition, hermetic stores by themselves also prevent pest damage. Grains can be stored in sacks of various types on both a small and large scale.

For medium- or long-term storage, hermetic sacks may be used when benefits outweigh costs.

In other situations, traditional mud stores (as well as more modern plastic or metal silos) may significantly reduce the postharvest losses of smallholders. Such stores may be hermetic or at least sufficiently sealed to prevent pest access to grain.

Read Also : Checklist for Waste Sampling

Frequently Asked Questions

We will update this section soon.