The floor of the concrete fish pond must be properly filled with concrete and well cemented in such a way to make it impervious to water. However, it must not be slippery so as not to pose danger to anyone entering the pond at any time.

In case the inlet is laid along the floor, it must be laid very close to the wall so that it doesn’t damage the floor nor case any injury to farm workers.

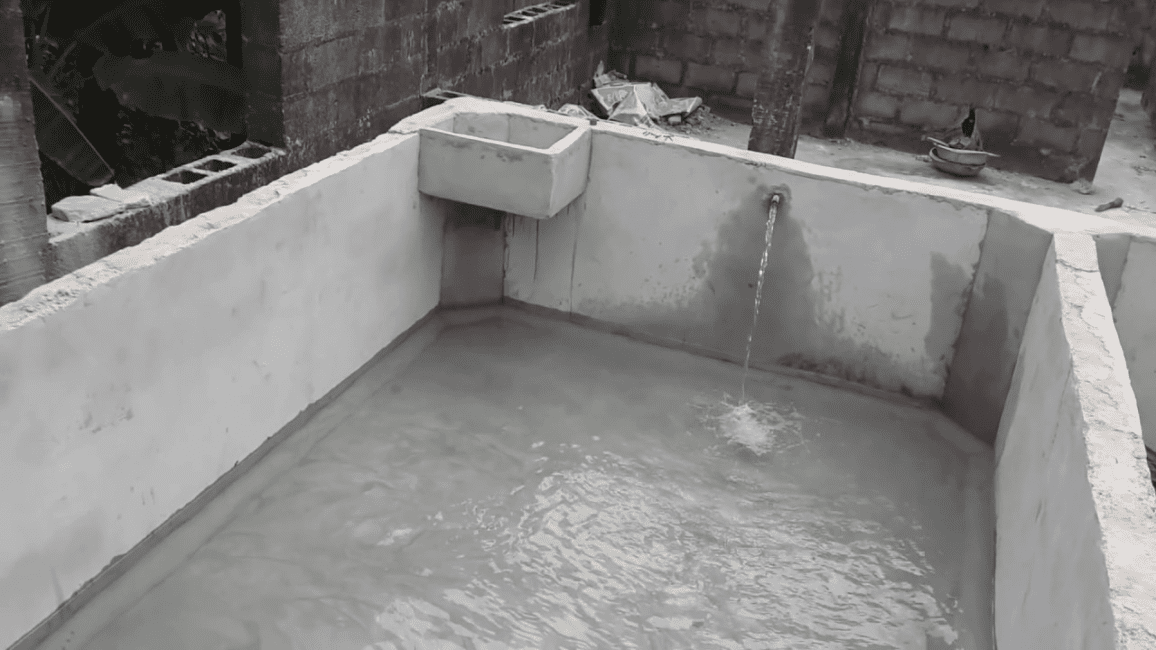

Building a Concrete Pond

Although concrete is now less commonly used to build ponds than it once was and certainly makes more demands on the builder than the alternatives, it does have some definite advantages which still make it a material worth considering.

Particularly when it comes to some kinds of more specialist water features especially those needing vertical walls such as traditional formal or koi ponds, there is not much to match the strength and rigidity of concrete.

In the days when concrete was used extensively for pond construction, the standard method involved pouring the mix into a mould made with wooden shuttering.

While this method allows for irregular shapes to be created, the concrete is prone to cracking and the rise of much cheaper liners and pre-formed ponds has almost entirely superseded this approach for natural-look water features. Most of today’s concrete ponds are built using breeze blocks, which are then skimmed with a sharp sand/cement/fibre glass mix.

Read Also: Concrete Pond Management: Steps to take before introducing the Fish in the Water

Starting the Construction

The construction process for this type of pond is relatively straight-forward, if somewhat time-consuming. The first step is to dig out the hole to the required size; since most concrete ponds are square or rectangular, it is worth taking the time to mark out the outline making sure that the angles are true, the lines are straight and the walls as near upright as possible.

Getting this right at the outset can save a lot of time and frustration in the long run since as the digging progresses, it can be surprisingly easy to drift off course. You should aim to go down around 5 – 6 inches (12 – 15cm) below the finished pond’s intended depth, to allow for the base.

Once the excavation for the actual body of the pond is complete, you’ll need to dig a trench for the foundations – about 4 inches (10cm) deep and 8 inches across (20cm) – around the outside of the hole to support the block-work. Once this has been completed, it needs to be filled with concrete and then allowed to dry thoroughly.

Next, the soil at the base of the hole should be raked level, a layer of sand added and then tamped down firmly to compact it well, making sure that it finishes level with the foundations.

Lay a 3inch (7.5cm) coat of concrete over the whole area and allow it to dry completely, before adding galvanised mesh for reinforcement and then finish off with a second 3inch (7.5cm) layer of concrete.

Make sure it has dried out thoroughly before continuing. The whole base now needs to be skimmed with a half-inch (12mm) coat of cement containing reinforcing fibres.

The purpose-made reinforcement fibres are designed to help prevent small cracks from appearing and makes the whole structure less likely to leak; they can be bought from most builders’ merchants and specialist water garden suppliers.

After 24 hours, once the cement base has had a chance to dry, the next step is to build the block-work walls, filling both the hollows in the blocks themselves and any gaps between them and the surrounding soil with concrete. A course or two of house bricks at the top of the block wall finishes the whole thing off neatly, providing a level edging for the pond.

Read Also: Importance of a Fish Net on a Concrete Pond

Finishing Off Your Pond

The walls need to be left to dry for at least another 48 hours, after which time they can be dampened slightly and then skimmed with a half-inch (12mm) layer of fibre-reinforced cement to match the base.

The final part of the real construction work calls for an edging layer of bricks or slabs to be mortared into place around the top of the wall, allowing an over-hang of a good 2 or 3 inches (5 or 7.5cm).

After a further 48 hours, the last step is to paint the inside of the structure with a good quality waterproof sealant – principally to stop the lime in the cement from leaching out into the water and causing problems for the plants and pond-life. Wait a few more days and then fill the pond.

It is always a good idea to check the pH of the water in a concrete pond to make sure it is around neutral – pH7 – before you start planting up or introducing any fish; if the pH is much higher than this, the conditions will be too alkaline for pond-life to thrive.

If this does occur, it doesn’t automatically mean that your attempts at sealing the concrete have failed, so it is worth waiting a few more days and testing again as the problem can sometimes be a short-lived one.

Building a concrete pond is undoubtedly a far larger undertaking than making one with any of the more common types of liner, but for some types of pond, it remains the best material for the job.

Although they take longer to complete and require much more in the way of effort, if you take your time and proceed carefully, a very durable and good-looking pond can be yours.

4 Types of Ponds Best for Fish Farming

Different fish farms use various kinds of ponds for holding, breeding, and fattening up fish. Even within a single fish farm, there may be a few different types of ponds for managing the fish.

The types of ponds that a particular fish farm uses are based on the species of fish being farmed, the scale of the operation, and the location of the property.

Earthen ponds are the most natural and common type used for large-scale aquaculture. They are great for raising catfish, tilapia, carp, koi, and goldfish. Above-ground ponds can be constructed of concrete, plastic, rubber, or PVC tarpaulin within a wooden, plastic, or metal frame.

The type of pond makes a massive difference in fishes’ health and growth rate. Therefore, if you plan on starting an aquaculture operation, you must carefully consider the type of ponds you use. Here, we discuss the four best and most popular types of ponds for fish farming.

1. Earthen Ponds

These are the most popular types of ponds used for fish farming. Most of the top fish farms in the world use earthen ponds. They allow fish to be kept in an almost natural environment.

Earthen ponds are relatively easy and inexpensive to construct, especially for large-scale aquaculture operations. However, they require land with a consistent water supply from a river or dam.

Earthen ponds can be constructed in several ways, but most often, they are built by digging a hole in the ground, much in the same way as dams are built.

The soil type is an important factor in determining whether an earthen pond is viable. Clay soils are the densest and do not allow water to seep down into the ground. Therefore, earthen ponds must be built in areas with clay soils so that they can hold water.

Where an earthen pond is sited is very important. The area should have a gentle slope so that inflow and outflow can easily be built.

The type of earthen pond that is built depends largely on the property’s water supply and the topography of the landscape. Let’s look at the different types of earthen ponds:

Dugout Ponds

This type of earthen pond is constructed by excavating an area to form a hole in the ground. The soil from the hole is placed around the sides of the pond to deepen it. Dugout ponds have floors that slope gently inward. The depth usually ranges from 1.5 to 1.8 meters.

Small dugout ponds can be dug manually (with considerable effort), and medium to large-scale ponds are constructed using a bulldozer, TLB, excavator, or a front-end loader. It helps to build these ponds in an area with an existing depression in the landscape.

Barrage Ponds

This type of pond is built within a river course on a valley bottom. A dam is built across the lower end of the valley.

An outlet is built at the bottom of the dam so that the pond can be gravity drained. A structure is built at the pond’s inlet so that water flowing in can be controlled. A spillway is built on one side of the dam to allow for overflow during floods.

Embankment Ponds

This type of pond does not need to be dug into the ground. Instead, above-ground dikes are built to hold water. Embankment ponds can be filled by pumping water from a nearby dam or reservoir.

Often, they are built with a drainage hole near the base of the dike so that they can easily be drained. This makes management significantly easier.

Cut and Fill Ponds

Cut and fill ponds are built on a gentle slope. The ground is excavated, and the soil is deposited in a dike on the lower end of the slope to hold the water.

They can be pump-fed or be fed by gravity flow from an inlet canal. A drainage hole is built in the dike so that the pond can be emptied.

Diversion Ponds

This type of pond is built adjacent to a river course and is dug into the ground (where the ground slopes) or built with four dikes on each side (where the ground is flat).

A diversion canal coming from a river feeds the pond, and an inlet structure allows control of the flow of water entering the pond. The water can flow in by gravity or through a pump. In addition, diversion ponds have an outlet canal that allows them to be drained when necessary.

Walled Ponds

Above-ground walled ponds are surrounded by brick, block, concrete, wooden planks, or corrugated metal sheets. The floor of the pond is earthen and can be slightly excavated to increase the depth.

Walled ponds are most often pump-fed and have a drainage hole near the base of the wall so that the pond can be emptied easily.

Lined Ponds

If the soil in an area where a pond needs to be built is not dense and clayey enough, a PVC or rubber pond liner can be used to keep water from seeping out of the pond.

Advantages of Earthen Ponds

There are many advantages to farming fish in earthen ponds:

- They can hold extensive fish stocks

- Fish grow more rapidly than in artificial ponds and are healthier

- Fish live in the most natural environment possible and can feed on natural food sources, like worms, vegetation, and algae

- They are relatively cheap to build and cost little to maintain

Disadvantages of Earthen Ponds

However, there are a few drawbacks to earthen ponds:

- They require a large amount of land to construct

- It is difficult to see the fish in the murky water, so it is hard to notice disease outbreaks

- They make sorting the fish into different sizes difficult, which increases the risk of cannibalism

- During floods, earthen ponds can break their dikes, leading to fish escaping, the pond water being polluted by surface runoff, and even the whole pond collapsing

Read Also: Farm Estate Planning and Transition for Farmers

2. Concrete Fish Ponds

Concrete fish ponds are the second most common type of pond used for farming catfish, tilapia, carp, and ornamental species. They are built above the ground, and the floor of the pond is concrete.

They range in size, but generally, concrete ponds are around 2 x 5 meters. They are perfect for fish that grow quickly and are sold as food.

Concrete ponds can be stagnant without an outlet. Water is pumped in and out when necessary. The water quality in a stagnant pond is lower, so the stocking rate is not very high. A 2 x 5 meter pond can hold 600 fish at most, and they will take longer to grow to table size.

Free-flow concrete ponds have an inflow and outlet, and there is a constant flow of water through the pond. A 2 x 5 meter pond can be stocked with 1000 to 1800 catfish. The fish grow fast because of the freshness of the water and the turbulence caused by the flow, which increases their feeding activity.

Concrete ponds can also have a water recirculation and filtration system. This helps to manage the water quality but does not waste the water that flows out of the pond, like in a free-flow system. These are the costliest to construct and require the most work because the pumps and filters need to be maintained.

Advantages of Concrete Ponds

There are several advantages to concrete ponds for fish farming:

- They can be built in places that do not have a stream or river nearby, allowing fish to be farmed in urban zones close to the market

- They are useful as holding ponds for fish that have reached table size and are ready and waiting to be sold

- They are great for using as breeding ponds to produce fingerlings

- The water in the pond is clear, so you can see the fish clearly and monitor their health

- They can easily be drained and allow you to manage the water quality

- Concrete ponds are not vulnerable to flood damage

Disadvantages of Concrete Ponds

There are a few disadvantages to concrete ponds:

- They are more costly to construct and maintain than earthen ponds

- Wastewater from the pond can be hazardous to the environment, as the nutrient-rich water causes eutrophication of natural watercourses

3. Plastic or Rubber Ponds

Plastic or rubber ponds are rigid, round containers that are used by many beginners in aquaculture. They are straightforward to install and can be filled from a reservoir using a pump. Near the bottom of the pond is an outlet so that the pond can easily be drained by gravity.

Like concrete ponds, water can be recirculated and filtered to maintain good water quality. Therefore, you do not need a river or dam to supply these ponds with water.

Advantages of Plastic or Rubber Ponds

These are the pros of farming fish in plastic or rubber ponds:

- They don’t need a large amount of space

- They can easily be emptied and moved (great for if you are renting a property)

- They can be used indoors and are easy to heat

- You can start with a small number of ponds and gradually get more as the farming operation grows

- They are very cost-effective and easy to maintain

Disadvantages of Plastic Or Rubber Ponds

Disadvantaged of plastic or rubber ponds for fish farms:

- Outside in the full sun, the plastic can degrade over time

- For large-scale aquaculture operations, needing to buy more and more plastic ponds to hold fish can get expensive

4. Tarpaulin Ponds

The fourth type of pond used for fish farming is a tarpaulin pond. These are above-ground ponds, like plastic or rubber ponds, but constructed from a flexible PVC tarpaulin material. The outer frame that the tarpaulin is attached to can be made from wood or galvanized metal pipes.

These ponds can be built in a range of different sizes. It is important to buy UV-stabilized, fish-safe PVC tarpaulin so that the material does not degrade in the sun and tear, causing a leak. This is disastrous for the fish inside!

Advantages of Tarpaulin Ponds

The pros of tarpaulin ponds are:

- They can be built anywhere – indoors, outdoors, in urban areas

- They do not need a running water supply

- They do not require a large area

- They are more cost-effective compared to concrete, plastic, or rubber ponds

- They can easily be drained, taken down, and moved

- Fish can easily be harvested by draining the pond

- It is easy to manage the water quality

Disadvantages of Tarpaulin Ponds

The main drawbacks of this type of pond relate to the nature of the flexible PVC tarpaulin material:

- It can easily be punctured or torn

- It can be damaged by heavy rainfall and foods

- They are vulnerable to being stolen due to how easy they can be disassembled

Read Also: Causes and Effects of Deforestation