Processing, packaging, and exporting poultry meat involves several key steps to ensure the meat is safe, high-quality, and ready for international markets. The process starts with raising and caring for poultry, typically chickens, turkeys, or ducks. Proper nutrition, housing, and health care are essential to producing healthy birds. Once the poultry reach the appropriate size and age, they are ready for processing.

The first step in processing poultry is slaughtering. The birds are humanely slaughtered following strict hygiene and animal welfare standards. This process begins with stunning, which renders the birds unconscious to minimize suffering. After stunning, the birds are bled by cutting the major blood vessels to ensure blood is fully drained from the carcass. This step is crucial for maintaining meat quality and safety.

After bleeding, the poultry are scalded in hot water to loosen the feathers. This makes plucking easier and more efficient. Once the feathers are removed, the birds are then eviscerated. Evisceration involves removing the internal organs, such as the heart, liver, and intestines. This step is done carefully to avoid contamination. The carcasses are then thoroughly washed to remove any remaining blood and impurities.

Following washing, the poultry carcasses are chilled to lower their temperature quickly. This helps to prevent bacterial growth and spoilage. The chilling process usually involves immersing the carcasses in ice-cold water or using air-chilling methods. The chilled carcasses are then inspected for quality and safety. This inspection ensures that the poultry meets all health standards before moving on to further processing.

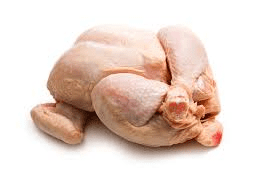

Once the poultry is inspected and approved, it is cut into various parts, such as breasts, thighs, wings, and drumsticks. The cutting is done by skilled workers or machines, depending on the scale of the operation. Each cut is trimmed and prepared to meet specific market demands. For whole poultry, the carcasses are often packed as is, while other cuts are further processed into products like nuggets or patties.

Packaging is an essential step in ensuring the poultry meat remains fresh and safe during transportation. The meat is packaged in airtight materials to prevent exposure to air and moisture. For fresh poultry, vacuum-sealing or using modified atmosphere packaging is common. For frozen poultry, the meat is packed in sturdy, freezer-safe containers or bags. Labels on the packaging include important information such as the type of cut, weight, expiration date, and any handling instructions.

Exporting poultry meat involves complying with international regulations and standards to ensure that the meat is safe and meets the importing country’s requirements. Exporters must obtain various certifications, such as health certificates, which confirm that the poultry has been inspected and meets safety standards. The meat must also be accompanied by documentation such as certificates of origin, which verify where the poultry was produced.

Transportation is a critical part of exporting poultry meat. The meat must be handled carefully to prevent damage and contamination. For fresh poultry, maintaining a cold chain is essential, meaning that the meat must be kept at a consistent, low temperature throughout transit. This is typically achieved using refrigerated containers. For frozen poultry, ensuring that the meat remains at the appropriate frozen temperature is crucial. Proper temperature monitoring during transport helps to maintain meat quality.

Upon reaching the destination country, the poultry meat goes through customs clearance. This involves inspecting the documentation and ensuring that the meat complies with the importing country’s regulations. If everything is in order, the meat is cleared for entry into the market. It is then distributed to retailers, wholesalers, or directly to consumers.

Processing, packaging, and exporting poultry meat involves several detailed steps to ensure the meat is high-quality and safe for consumers. From humane slaughtering and careful processing to effective packaging and compliance with export regulations, each step is crucial in delivering a product that meets global standards. By following best practices throughout the entire process, producers and exporters can provide poultry meat that satisfies international customers and adheres to regulatory requirements.

How to Process Poultry Meat for Exportation

1. Animal Selection: Choose healthy birds for slaughter. Conduct a thorough health check to ensure they are free from diseases and infections. Healthy birds yield better quality meat, essential for export standards.

2. Slaughtering: Transport the selected birds to a certified slaughterhouse. Follow humane slaughtering practices, which are required by most countries’ regulations. This process typically involves stunning the birds before slaughter to minimize stress and ensure meat quality.

3. Bleeding: Hang the birds upside down and cut the major blood vessels in the neck to allow thorough bleeding. Proper bleeding is crucial to improve meat quality and shelf life. This step is done immediately after slaughtering.

4. Scalding: Dip the birds in hot water (50-60°C) to loosen feathers. Scalding time varies depending on bird size but usually takes a few minutes. This step makes feather removal easier.

5. Plucking: Remove feathers from the scalded birds using mechanical pluckers or by hand. Mechanical pluckers are more efficient and provide consistent results. Ensure all feathers are removed to meet export quality standards.

6. Evisceration: Remove the internal organs from the birds. This process should be done carefully to avoid contamination. The organs can be inspected and disposed of or processed as per regulations.

7. Washing: Thoroughly wash the carcasses to remove any remaining blood, feathers, and contaminants. Use clean, potable water and ensure all surfaces of the birds are cleaned. This step helps in maintaining hygiene and meat quality.

8. Chilling: Chill the carcasses to a temperature of 0-4°C to prevent bacterial growth. Rapid chilling is essential to maintain meat quality and extend shelf life. Use ice or cold air systems for chilling.

9. Deboning (Optional): Depending on the market requirements, debone the chilled carcasses. This step requires skilled labor to ensure maximum meat yield and minimal waste. Deboned meat is easier to package and transport.

10. Trimming: Trim excess fat and unwanted parts from the meat. Proper trimming enhances the appearance and quality of the meat. This step should be done carefully to retain maximum meat.

11. Cutting: Cut the meat into desired portions or products as per market requirements. This can include whole birds, parts like breasts, thighs, wings, or ground poultry. Use sharp knives or meat saws for precise cuts.

12. Quality Control: Inspect the meat for quality and compliance with export standards. This includes checking for proper color, texture, and absence of contaminants. Quality control ensures that the meat meets customer expectations.

13. Packaging: Pack the processed meat in suitable materials to maintain freshness. This can include vacuum-sealing or using modified atmosphere packaging. Proper packaging prevents contamination and extends shelf life.

14. Labeling: Label each package with essential information such as product name, weight, origin, and processing date. Include any specific details required by the importing country, such as certification marks or handling instructions.

15. Freezing: Freeze the packaged meat at -18°C or lower to preserve quality. Rapid freezing prevents ice crystal formation, which can damage meat texture. Ensure consistent freezing to maintain product quality.

16. Storage: Store the frozen meat in a clean, temperature-controlled environment. Proper storage prevents spoilage and maintains meat quality. Ensure regular temperature monitoring to prevent any issues.

17. Documentation: Prepare all necessary export documentation, including health certificates, certificates of origin, and compliance with international standards. Accurate documentation is crucial for smooth customs clearance.

Read Also: Rice Tungro Disease: Description, Damages Caused, Control and Preventive Measures

How to Package Poultry Meat for Exportation

1. Select Packaging Materials: Choose strong and protective packaging materials such as vacuum-sealed bags, plastic trays with film, or boxes with liners. These materials should protect the meat from contamination and freezer burn.

2. Determine Packaging Size: Decide on the size and weight of the packages based on customer requirements and shipping logistics. Common sizes include whole birds, parts, or portion-controlled packs.

3. Vacuum Sealing: Vacuum-seal individual cuts or portions to remove air and extend shelf life. This method prevents freezer burn and maintains meat quality. Use high-quality vacuum-sealing equipment for best results.

4. Modified Atmosphere Packaging (MAP): For certain products, use MAP to extend shelf life. This involves replacing the air inside the package with a gas mixture to slow down spoilage. This method is particularly useful for fresh poultry.

5. Label Packages: Clearly label each package with essential information such as product name, weight, origin, processing date, and expiration date. Include any specific details required by the importing country, such as certification marks or handling instructions.

6. Include Documentation: Attach necessary export documents such as health certificates, certificates of origin, and packing lists to each package or keep them readily available for customs inspection.

7. Use Cushioning: For delicate or high-value meat products, use cushioning materials like bubble wrap or foam inserts to provide extra protection. This helps prevent any damage during handling and transport.

8. Palletize: Arrange the packages on pallets for bulk shipments. Secure the packages with straps or shrink wrap to prevent them from shifting during transit. Palletizing improves handling efficiency and protection.

9. Inspect Packaging: Check that all packages are properly sealed, labeled, and free from defects. Ensure there are no damaged or compromised packages to avoid issues during shipping and customs clearance.

10. Cold Storage: Store packaged meat in a temperature-controlled environment until it is ready for shipment. Maintain a consistent temperature to prevent spoilage and ensure the meat remains frozen.

How to Export Poultry Meat for Profits

1. Conduct Market Research: Research potential markets and identify countries with high demand for poultry meat. Understand market trends, prices, and competition to position your product effectively.

2. Understand Export Regulations: Familiarize yourself with export regulations and requirements for the target market. This includes tariffs, import restrictions, and quality standards specific to poultry meat.

3. Find Reliable Buyers: Reach out to potential buyers, importers, or distributors in your target market. Attend trade shows, join industry associations, and use online platforms to connect with buyers interested in poultry meat.

4. Set Competitive Pricing: Determine a competitive pricing strategy based on production costs, market demand, and profit margins. Consider factors such as quality, packaging, and volume discounts when setting prices.

5. Negotiate Terms and Conditions: Negotiate terms with buyers including payment terms, delivery schedules, and contract conditions. Ensure that both parties agree on these terms before finalizing the export deal.

6. Arrange Logistics: Coordinate logistics and transportation to ensure timely and safe delivery of poultry meat. Choose reliable logistics providers who specialize in handling perishable goods.

7. Monitor Quality: Implement quality control measures to ensure the meat meets export standards. Regularly inspect the products during processing and packaging to address any issues before shipment.

8. Prepare Documentation: Complete all required export documentation accurately and in compliance with international trade regulations. This includes invoices, packing lists, health certificates, and other necessary documents.

9. Promote Your Product: Invest in marketing and promotional activities to increase visibility and attract more buyers. Use online marketing, social media, and trade publications to reach a broader audience.

10. Evaluate and Adjust: Regularly review your export performance and customer feedback. Make adjustments to your strategy as needed to improve profitability and expand your market reach.

Read Also: 8 Medicinal Health Benefits of Populus Grandidentata (Bigtooth Aspen)

Frequently Asked Questions (FAQ’s) About Poultry Meat

1. What is the best way to store poultry meat before export? The best way to store poultry meat is in a clean, temperature-controlled environment, ideally frozen at -18°C or lower to preserve quality and prevent spoilage.

2. How is poultry meat inspected for export? Poultry meat is inspected for export through government-regulated programs that ensure the meat meets health and safety standards. This includes checking for diseases, contaminants, and proper handling practices.

3. What are the main export markets for poultry meat? Major export markets for poultry meat include the United States, China, Japan, South Korea, and the European Union. These regions have high demand for quality poultry products.

4. What documentation is required for exporting poultry meat? Necessary documentation includes health certificates, certificates of origin, export licenses, and compliance with international standards. Accurate documentation ensures smooth customs clearance.

5. How does vacuum sealing benefit poultry meat export? Vacuum sealing removes air from the package, extending shelf life and preventing freezer burn. This method maintains the quality and freshness of the meat during transit.

6. What are the challenges in exporting poultry meat? Challenges include meeting stringent import regulations, maintaining cold chain logistics, and managing tariffs and trade barriers. Addressing these challenges is crucial for successful exportation.

7. How can exporters find reliable buyers for poultry meat? Exporters can find buyers by attending trade shows, joining industry associations, using online platforms, and building relationships with importers and distributors in target markets.

8. What is the role of quality control in poultry meat export? Quality control ensures that the poultry meat meets export standards and customer expectations. It involves regular inspections during processing, packaging, and storage to maintain high quality.

9. How can exporters promote their poultry products? Exporters can promote their products through online marketing, social media, trade publications, and participating in food fairs and exhibitions. Effective promotion helps attract more buyers and expand market reach.

10. What factors affect the pricing of poultry meat for export? Factors affecting the pricing include production costs, market demand, quality of the meat, packaging, transportation costs, and tariffs. Competitive pricing strategies are essential to attract and retain buyers.

Read Also: Potato Farming Guide – 7 Tips to Grow Sacks Full of Potatoes