Rubber Laticifers are specialized cells found in the sap of rubber trees. These cells produce and store latex, a milky white fluid that contains rubber particles. The latex can be harvested from the trees and processed into rubber products.

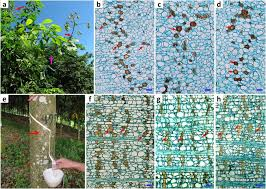

The rubber tree, also known as Hevea brasiliensis, is native to South America but is now widely cultivated in tropical regions around the world. The tree grows up to 100 feet tall and can live for up to 100 years. The latex is harvested by making small incisions in the bark of the tree and collecting the fluid in small cups attached to the trunk.

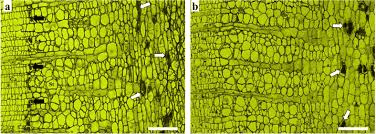

Rubber Laticifers are unique in that they are living cells that are capable of producing and storing large amounts of latex. The cells are elongated and form a network throughout the tree. The latex is produced in small vesicles within the cell and is released when the cell is damaged or stimulated.

The latex produced by the Rubber Laticifers contains a mixture of organic compounds, including proteins, sugars, lipids, and alkaloids. The rubber particles are suspended in the latex and are made up of a polymer called polyisoprene. The polyisoprene molecules are long chains of repeating units that are cross-linked to form a network.

The Rubber Laticifers play an important role in the growth and development of the rubber tree. The latex provides a protective barrier against insects and other pests, as well as protecting the tree from physical damage. The latex also contains growth hormones and other signaling molecules that regulate the growth and development of the tree.

The rubber produced by the Rubber Laticifers is an important industrial material that is used in a wide range of products, including tires, hoses, belts, gloves, and footwear. The processing of the latex into rubber products involves several steps, including coagulation, washing, and drying. The coagulation process involves the addition of an acid or other chemical to the latex, which causes the rubber particles to clump together and separate from the liquid. The resulting rubber is then washed to remove impurities and dried to remove excess moisture.

In conclusion, Rubber Laticifers are specialized cells found in the sap of rubber trees that produce and store latex, which is used to make rubber products. The cells are unique in that they are living cells that are capable of producing and storing large amounts of latex. The latex contains a mixture of organic compounds, including proteins, sugars, lipids, and alkaloids, and the rubber particles are made up of a polymer called polyisoprene. The Rubber Laticifers play an important role in the growth and development of the rubber tree, providing protection against insects and other pests, as well as regulating growth and development.

The Economic Importance and Uses of Rubber Laticifers

1. Rubber Production: Rubber laticifers play a crucial role in the production of natural rubber, a valuable commodity used in various industries worldwide. The latex produced by laticifers serves as the primary raw material for rubber manufacturing.

2. Automotive Industry: Natural rubber derived from rubber laticifers is used extensively in the automotive industry for manufacturing tires, hoses, belts, seals, gaskets, and other rubber components. These rubber products are essential for vehicle performance, safety, and durability.

3. Construction Sector: Rubber laticifers contribute to the construction sector by providing materials for waterproofing, insulation, sealing, and damping applications. Rubber-based products such as sealants, adhesives, roofing materials, and insulation foams are commonly used in construction projects.

4. Healthcare Sector: Latex gloves, catheters, tubing, and other medical devices made from natural rubber are vital components in the healthcare sector. Rubber laticifers play a significant role in supplying these medical products, which are essential for patient care and medical procedures.

5. Textile Industry: Natural rubber extracted from laticifers is used in the textile industry to produce elastic fibers and fabrics for clothing, undergarments, sportswear, swimwear, and other textile products. Rubber-based elastic materials provide stretchability, comfort, and durability in textiles.

6. Consumer Goods: Rubber laticifers are used in the manufacturing of various consumer goods such as rubber bands, erasers, shoe soles, toys, grips, and household products. These rubber items serve everyday needs in households, schools, offices, and recreational activities.

7. Agriculture and Farming: Rubber laticifers contribute to agriculture and farming by providing materials for irrigation systems, hoses, tubing, seals, and gaskets used in agricultural machinery, equipment, and irrigation systems. Rubber-based products help improve efficiency and productivity in agriculture.

8. Packaging Industry: Rubber laticifers are used in the packaging industry to produce rubber seals, gaskets, closures, and protective packaging materials. Rubber-based packaging solutions provide airtight seals, cushioning, and protection for various products during storage and transportation.

9. Electrical Engineering: Natural rubber derived from laticifers is used in electrical engineering applications for manufacturing insulation materials, cables, wires, seals, and gaskets. Rubber-based electrical components provide insulation, protection, and reliability in electrical systems.

10. Sporting Goods: Rubber laticifers contribute to the sporting goods industry by providing materials for manufacturing sports equipment such as balls, grips, mats, padding, and protective gear. Rubber-based sporting goods offer durability, shock absorption, and performance in sports activities.

11. Marine Industry: Rubber laticifers play a role in the marine industry by providing materials for manufacturing marine seals, gaskets, hoses, fenders, and other rubber components used in boats, ships, docks, and marine equipment. Rubber-based marine products offer resistance to water, salt, and environmental conditions.

12. Mining Sector: Rubber laticifers are used in the mining sector for manufacturing conveyor belts, seals, hoses, liners, and other rubber products used in mining operations. Rubber-based mining equipment provides durability, abrasion resistance, and reliability in harsh mining environments.

13. Environmental Applications: Rubber laticifers contribute to environmental applications by providing materials for manufacturing pollution control devices, landfill liners, water treatment components, and environmental protection equipment. Rubber-based solutions help mitigate environmental impact and promote sustainability.

14. Aerospace Industry: Natural rubber extracted from laticifers is used in the aerospace industry for manufacturing seals, gaskets, hoses, vibration isolators, and other rubber components used in aircraft, spacecraft, and aerospace equipment. Rubber-based aerospace products offer reliability and performance in aerospace applications.

15. Oil and Gas Sector: Rubber laticifers are used in the oil and gas sector for manufacturing seals, gaskets, hoses, piping, and other rubber components used in drilling, exploration, production, and refining operations. Rubber-based products provide resistance to oil, chemicals, and high temperatures in oil and gas applications.

16. Furniture Manufacturing: Rubber laticifers contribute to furniture manufacturing by providing materials for manufacturing upholstery, padding, cushions, and ergonomic components. Rubber-based furniture components offer comfort, support, and durability in residential, commercial, and industrial furniture.

17. Recreational Equipment: Rubber laticifers are used in recreational equipment manufacturing for producing grips, handles, padding, mats, and protective gear used in sports, fitness, outdoor activities, and leisure pursuits. Rubber-based recreational products enhance performance, safety, and comfort in recreational activities.

Read Also The Reproductive Rate of Cattle

The Products and By-products That Can Be Derived From Rubber Laticifer

1. Natural Rubber: The primary product derived from rubber laticifers is natural rubber latex, which serves as the raw material for manufacturing various rubber products.

2. Rubber Sheets: Natural rubber latex extracted from laticifers is processed into rubber sheets through coagulation, rolling, and drying processes. Rubber sheets are used in tire manufacturing and other rubber product applications.

3. Latex Gloves: Natural rubber latex from laticifers is used to manufacture latex gloves for medical, laboratory, and household use.

4. Rubber Condoms: Natural rubber latex derived from laticifers is used in the production of latex condoms for contraception and protection against sexually transmitted infections.

5. Rubber Adhesives: Latex from rubber laticifers is used in the formulation of rubber adhesives for bonding various materials in construction, automotive, and industrial applications.

6. Latex Foam: Rubber laticifers contribute to the production of latex foam used in mattresses, pillows, cushions, and upholstery for comfort and support.

7. Rubber Flooring: Rubber laticifers provide materials for rubber flooring used in residential, commercial, and industrial settings for durability, slip resistance, and sound insulation.

8. Rubber Mulch: Ground rubber bark derived from laticifers is used as mulch in landscaping and gardening applications for weed suppression and soil moisture retention.

9. Rubberized Asphalt: Rubber laticifers contribute to rubberized asphalt production, which is used in road construction for improved durability and performance.

10. Rubber Mats and Tiles: Rubber laticifers provide materials for manufacturing rubber mats and tiles used for flooring, playgrounds, gyms, and industrial applications.

11. Rubber Seals and Gaskets: Latex from rubber laticifers is used to manufacture seals and gaskets for automotive, machinery, and industrial equipment.

12. Rubber Bands: Rubber laticifers contribute to the production of rubber bands used for bundling, securing, and organizing items in various applications.

13. Dipped Products: Rubber laticifers are used to produce dipped products such as gloves, balloons, and medical devices through the dipping process.

14. Rubberized Textiles: Latex from rubber laticifers is applied to textiles to create waterproof, stretchable, and abrasion-resistant fabrics for apparel and outdoor gear.

15. Rubber Fuel Additives: Rubber laticifers provide materials for rubber fuel additives used to improve fuel efficiency and engine performance in automotive and industrial applications.

16. Rubberized Coatings: Rubber laticifers contribute to the production of rubberized coatings used for waterproofing, corrosion protection, and surface enhancement.

17. Rubber Molds and Castings: Rubber laticifers are used to create molds and castings for reproducing detailed shapes in manufacturing, art, and prototyping applications.

Read Also Scrapie in Sheep and Goats: Description, Damages Caused, Control and Preventive Measures

Frequently Asked Questions (FAQ’s) About Rubber Laticifers

1. What are rubber laticifers?

Rubber laticifers are specialized cells found in the inner bark of rubber trees (Hevea brasiliensis) that produce and store latex, a milky fluid containing rubber particles. These cells play a vital role in the synthesis and secretion of natural rubber.

2. How is latex extracted from rubber laticifers?

Latex is extracted from rubber laticifers through a process called tapping, which involves making shallow incisions in the bark of rubber trees and collecting the latex that flows out. The collected latex is then processed to remove impurities and stabilize it for various applications.

3. What is the economic importance of rubber laticifers?

Rubber laticifers are economically important as they are the primary source of natural rubber, a valuable commodity used in industries such as automotive, healthcare, construction, textiles, and consumer goods. Rubber cultivation and latex extraction provide livelihoods for millions of people worldwide.

4. What are the main uses of natural rubber derived from rubber laticifers?

Natural rubber derived from rubber laticifers is used in the production of various rubber products such as tires, gloves, condoms, medical devices, adhesives, foam, flooring, mulch, and asphalt. These rubber products have diverse applications in different industries.

5. Are there any environmental concerns associated with rubber laticifers?

Rubber cultivation and latex extraction can have environmental impacts such as deforestation, habitat loss, soil degradation, water pollution, and biodiversity loss. Sustainable rubber cultivation practices and certification schemes aim to mitigate these environmental concerns and promote responsible rubber production.

6. What are some alternatives to natural rubber derived from rubber laticifers?

Some alternatives to natural rubber derived from rubber laticifers include synthetic rubber produced from petrochemicals, bio-based rubber derived from renewable resources such as guayule and dandelion plants, and recycled rubber obtained from scrap tires and other rubber products.

7. Are there any health risks associated with handling latex from rubber laticifers?

Some people may develop latex allergies or sensitivities from repeated exposure to natural latex derived from rubber laticifers. Latex allergy symptoms can range from mild skin irritation to severe respiratory reactions. Proper handling and protective measures are recommended when working with latex products.

8. How can rubber laticifers be sustainably managed?

Rubber laticifers can be sustainably managed through practices such as agroforestry, biodiversity conservation, soil and water management, waste reduction, and community engagement. Sustainable rubber cultivation practices aim to balance economic, environmental, and social considerations.

9. What are some innovations in rubber laticifer technology?

Recent innovations in rubber laticifer technology include genetic engineering of rubber trees for improved latex yield and quality, development of sustainable tapping methods to reduce environmental impact, and utilization of by-products such as biomass and bioenergy from rubber cultivation.

10. How can consumers support sustainable rubber laticifer production?

Consumers can support sustainable rubber laticifer production by choosing products made from responsibly sourced natural rubber, supporting certification programs such as the Forest Stewardship Council (FSC) and the Roundtable on Sustainable Palm Oil (RSPO), and advocating for environmentally friendly rubber policies and initiatives.